Consumption habits have changed over the past two years due to the pandemic, even though the trend had already started before then. Due to factors linked to food safety and a quicker ways to shop, packaged products continue to gain popularity.

GNA, a company located in Ozzano dell'Emilia (Bologna) specializing in the production and sale of and assistance for food and non-food packaging machinery and systems, reports that "one of the most versatile, inexpensive and safe packaging options are flow packs, as they guarantee the integrity of the products, especially if they are perishable or delicate."

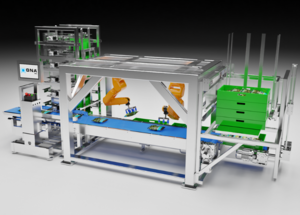

"Flow packs are available for various categories: avocadoes, tomatoes, apples, citrus fruit, kiwifruit, garlic, carrots, strawberries and broccoli, to name a few. For the packaging of round fruit, we have specifically created horizontal flow pack packager Vaquita. It is a reliable machine that can be customized, suitable for the high-performance packaging of loose fruits/vegetables and small trays. In addition, Vaquita can be supplied with an automatic synchronizer for the feeding and packaging of trays at high speed."

The feeding line is made up of three chains with a wider table top, newly-designed silicone teeth suitable to transfer nude and delicate products, anti-friction side belts, upper rail belt to receive and drive the products to the sealing area, lower belts that gently guide the products out of the machine.

Vaquita is very flexible and modular: it is in fact possible to extend the infeed to obtain a smoother production cycle. In terms of speed, its performance is up to 80 cycles/min, compatibly with the specific characteristics of each product.

"One of the advantages of our machine is that there is no friction during transport, so the produce is not damaged. In addition, it is also possible to package single fruits (see video below)"