The markets are focused on sustainability

"Sustainability is now one of the most important factors in all industries," according to Italy's company GNA, which recently attended two international trade fairs, Fachpack in Nuremberg and Fruit Attraction in Madrid.

"Once again, it has become clear that the sector is very much focused on environmental sustainability, including the use of environmentally friendly packaging materials," said the management who attended the two events. "Various solutions are available: paper in different thicknesses, also coupled with biodegradable/recyclable films; parchment, in different degrees of transparency; recyclable plastics; biodegradable materials; compostable materials; nets in biological materials and textile fibers; sheaths in PLA + paper."

.jpg)

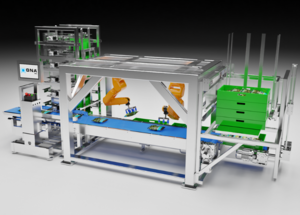

GNA's AV550 flowpack packaging machine (Photo: GNA)

Technologies are also evolving, and Italy's GNA is also showing no signs of slowing down. For several years now, it has offered its customers versatile machines capable of handling many types of different materials and minimizing the use of packaging materials.

Machines, such as the AV550, are precisely made to package individual products without having to use trays. This can be done with different types of materials for flowpack and shrink packaging. "In addition to traditional or flexible films of the new generation, the machine can also process paper. With the sliding welding head, the box motion version, and the reel in the lower part of the machine, irregular products, even without a tray, with variable lengths and shapes, with or without sheet, can easily be handled and packed."

In the case of fruits and vegetables, we are talking about difficult-to-handle products such as white cabbage, broccoli, and head lettuce, as well as stem vegetables such as celery, fennel, and leeks.

.jpg)

The AV550 machine has a strong presence in the Italian market and beyond, thanks to its great reliability and flexibility. "The advanced but user-friendly electronics manage all the functions of the packaging machine, including the specific accessories, such as seal bars for special applications, kits for shrink film, and modified atmosphere packaging. Through the reader belt with photocell, the machine easily recognizes products with open leaves or with bunches, such as bananas. Feeding is done by means of a conveyor belt, which comes with the machine," explained the company.

The flowpack packaging machine can be equipped with upstream and downstream devices, such as shrink tunnels, for example. It can therefore be integrated into complex production lines.

Main technical specifications of the AV550 packaging machine

AV550 is capable of packing various bulk products in flowpack and shrink film, as well as trays of 20x30, 30x40, and 30x50 cm. It reaches a maximum speed of 60-70 cycles per minute, with an electrical absorption of 3.5 KW and compressed air consumption of 270 NL/min.