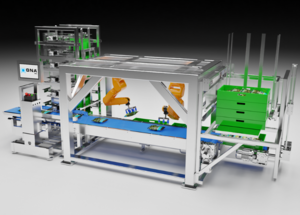

Robinia - packaging of fresh-cut, dried fruit and frozen products

Robinia, the continuous packaging machine manufactured by GNA was developed with the aim of meeting as many requests and needs as possible. It is a considerable leap forward as, so far, the company had been known only for its intermittent machines.

"Although ours is a medium-small business, we boast a diversified range of machines and manage to be versatile with technologically-advanced innovations and solutions that meet all kinds of needs. This latest introduction meets the need to achieve a better performance in terms of productivity, especially when it comes to single-product lines and to frozen and industrial products," report the company managers.

Massimiliano Nucci, Valerio Nucci, Gabriella Bolzoni, Carlo Iannuzzi and Loris Di Paolo from GNA at Macfrut 2023

Robinia can package dry and wet products in bags of different shapes and sizes

"The machine is destined for qualified operators in the fresh-cut, dried fruit, frozen product and industrial processing sectors. It has been designed for packets up to 350 mm wide with a maximum packaging speed of 100 Rpm. It has an AISI 304 stainless steel open frame and guarantees the maximum levels of sanitization also in difficult environments."

.jpg)

Rendering of packets obtained with the Robinia continuous vertical packager by GNA

Robinia can package products using plastic and compostable flexible films, single-materials, laminates, paper (alone or paired with other materials such as flexible films, cellulose and naturflex, compostable films, Pla) and paper+nets (also fabric).

"In addition to the new electronic platform that enables our machine to operate in box motion mode with higher welding times and pressure, thus obtaining the same performance of a machine with a rotating jaw, Robinia also boast an innovative hot air longitudinal welding system and a packaging material conveyor technology that uses belts and a suction system. This helps eliminate attrition between the film and the forming tube, and the continuous operation reduces the stress the material is subjected to, improving performance."

.jpg)

Rendering of packets obtained with the Robinia continuous vertical packager by GNA

Robinia can package products using plastic and compostable flexible films, single-materials, laminates, paper (alone or paired with other materials such as flexible films, cellulose and naturflex, compostable films, Pla) and paper+nets (also fabric).

"In addition to the new electronic platform that enables our machine to operate in box motion mode with higher welding times and pressure, thus obtaining the same performance of a machine with a rotating jaw, Robinia also boast an innovative hot air longitudinal welding system and a packaging material conveyor technology that uses belts and a suction system. This helps eliminate attrition between the film and the forming tube, and the continuous operation reduces the stress the material is subjected to, improving performance."

Source: Freshplaza.