The horizontal pillow package can be used in food and non-food sectors. In fact, it protects the freshness, integrity, crumbliness, softness of various foods and is particularly suited to both multipack and single packs.

Advantages:

Thanks to the different types of films and trays used, this kind of packaging preserves the characteristics of the product for a long time, whether it is a dry or fresh product. This packaging style is practical for both display and consumption purposes.

Customization:

The horizontal pillow packaging is widely variable in size and format, it fits to different types of products and to various trays and punnets.

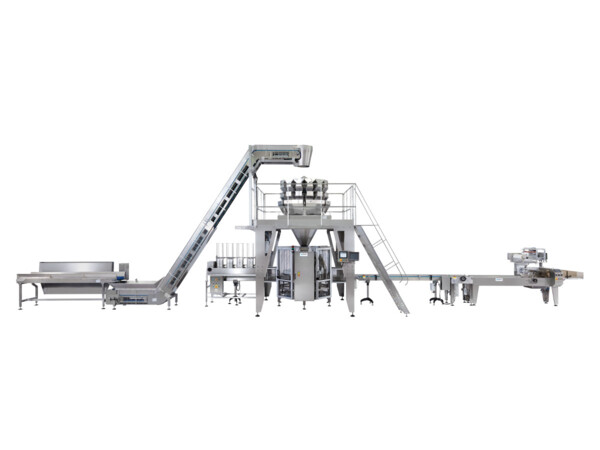

Machines for packs Horizontal pillow

This line is a complete solution to create perfectly packed products, whose qualities are fully preserved.

The line consists of a flow pack packaging machine Mod. Green HS and of an automatic feeding system Mod. NT286

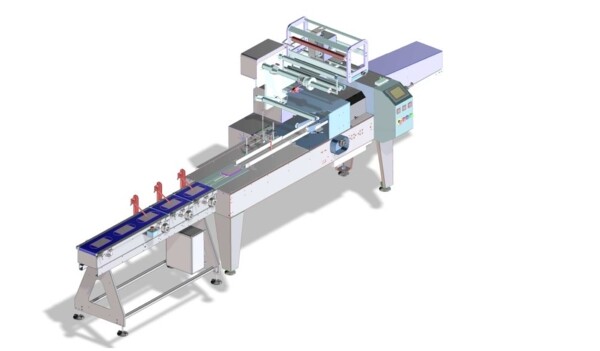

Chimera is a “Box Motion” horizontal flow-pack packaging machine with translation of the transversal jaws, up-to-down film reel; the product is driven into the sealing area on the machine infeed with a central chain and pushers. It packs up to 80 packs per minute.

| Product width | min 70 - max 200 mm |

| Clearance between jaws | max 240 mm |

Special flow-wrapper for packaging round fruits with and without trays. It produces up to 80 packs/min.

| Product width | min 70 - max 200 mm |

| Clearance between jaws | max 105 mm |

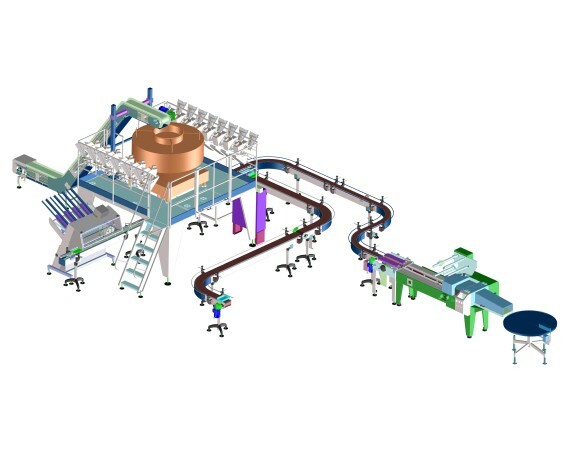

Weighing, filling and packaging line for trays with mushrooms

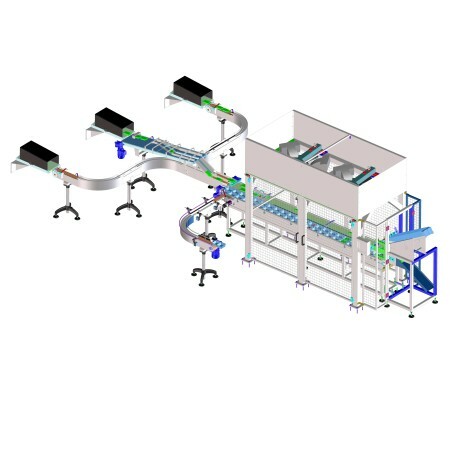

Flow pack packaging line with Pick & Place system

Fully automatic machine, for high performance. Equipped with a multifunctional Touch Screen, it can pack any kind of solid, food and non-food product, reaching a maximum speed of 150 cycles / min.

| Product width | min 70 - max 300 mm |

| Clearance between jaws | From 160 to 210 mm |

Fully automatic flow pack horizontal packaging machine, Top of the range, suitable for packing food and non food products, both with tray and loose. Double reel-holder, automatic sealing temperature adjustment, automatic product length reading. It packs up to 70 packs per minute.

| Product width | min 70 - max 300 mm |

| Clearance between jaws | max 300 mm |

Compact, versatile and reliable. Highly customizable, its structure in stainless steel makes it suitable for packing products in several industry sectors like fruit&vegetables, bakery, dairy, confectionery. Produces up to 90 packs per minute.

| Product width | min 70 - max 200 mm |

| Clearance between jaws | max 195 mm |

Its infeed belt system makes it ideal for packing any produce loose or in boxes, other food products but also non-food products. Can pack variable-dimensions products. It produces up to 60 packs per minute.

| Product width | min 120 – max 300 mm |

| Clearance between jaws | min 30 – max 200 mm |

Simple and small-sized packaging machine, packs trays in different sectors, produces up to 50 packs per min.

| Product width | max 200 mm |

| Clearance between jaws | max 90 mm |

Compact, versatile and reliable. Highly customizable machine, ideal for packing fruit&vegetables, bakery, confectionery. Seals up to 80 products per minute. One of the best values for money on the market.

| Product width | min 70 - max 200 mm |

| Clearance between jaws | max 195 mm |

Horizontal pillow

Horizontal pillow

Vertical pillow

Vertical pillow

Square bottom

Square bottom

4 Vertical sealings

4 Vertical sealings

Stretch

Stretch